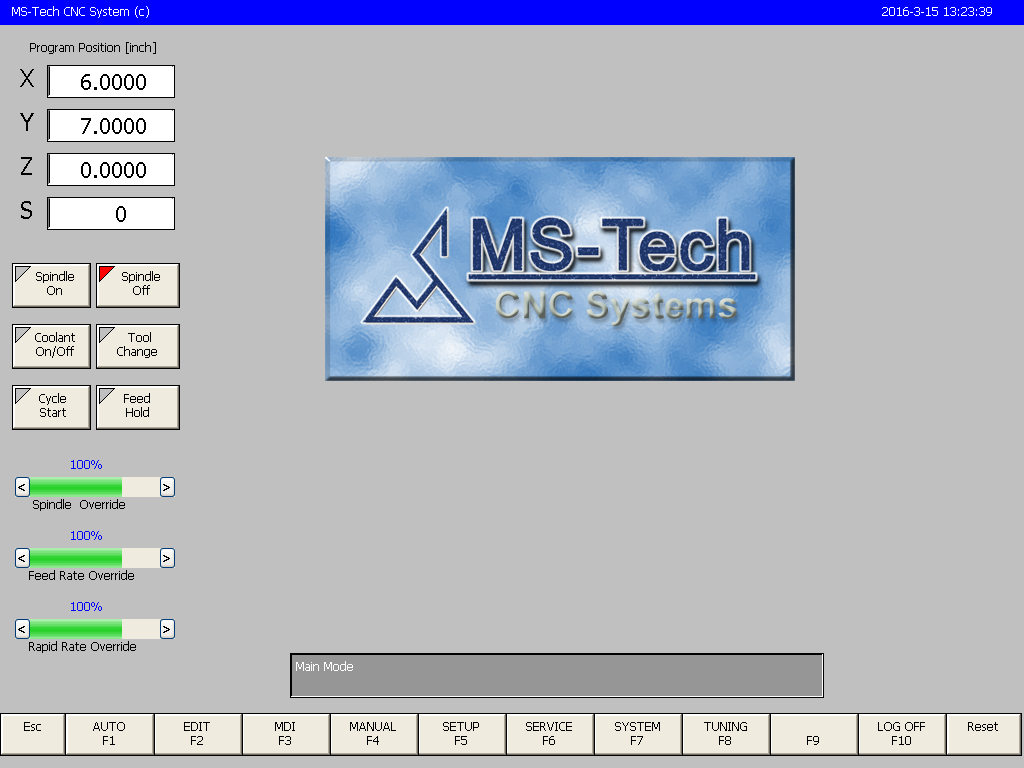

CNC Machine Control Retrofit Package

Core User Features & Functions:

The following core functions are only a portion of MS-Tech’s CNC control’s capabilities. MS-Tech’s CNC system is Fanuc G-Code compatible. Programs originally written for Yasnac control also run well for machines with new MS-Tech control.

The MS-Tech CNC control comes with the following major functions:

- Automatic mode for running NC program, including, single-step, optional stop, block skip, restart functions, etc.

- Edit mode for CNC program editing, including find/replace, G-code help, M-code help, go to a line/block, etc.

- MDI (Manual Data Input) mode for entering and executing CNC commands block by block, which may be selected from command history listing.

- Manual mode for homing, jogging by hand-wheel or by key, etc.

- Setup mode for tool offset and work offset data editing including offset measurement function, etc.

- Service mode for machine diagnosis, including ladder logic diagnosis, error message tracking, etc.

- Simulation function for verifying CNC programs before running

- Standard G-code and M-code programming per convention, and canned cycles are included.

- Search program either by block number or by line number

- Inch/mm automatic conversion for tool and work offsets

The following features have been designed to enhance the user experience:

- Built-in 3-D tool path display

- Built-in conversational programming

- Program down/up load from/to USB flash disk or RS-232C com port

- Super user-friendly — most people master the operation within 20 minutes

- Easy subprogram handling

Easy Installation:

MS-Tech’s CNC control is a combination of state-of-the-art quality hardware and advanced software for CNC machines. Each component of MS-Tech’s hardware and software was designed for straight forward installation and user-friendly operation.

As a result, MS-Tech’s Cincinnati VC Series CNC retrofit package contains both CNC and PLC components needed to make the CNC machine fully operational. MS-Tech CNC control sends +/- 10V command signals to servo and spindle drives, and accepts quadrature encoder-type signals for feedback.

Typically, MS-Tech’s CNC system interfaces with existing motors and drives seamlessly, allowing you to replace the old CNC control while keeping the good motors and drives, to achieve a more efficient (in both time and money) retrofit process. In case your servo or spindle drive on the machine has problem, please contact MS-Tech for retrofit solution with new motors and drives.

MS-Tech provides a full installation manual and allows for free, unlimited email-based technical support. You will be surprised at how easy the control system is to install and use.

The following is provided to assist your installation process:

- PDF Installation manual

- Retrofitting checklist

- Reference wiring diagrams

- Licensed CNC Software pre-installed

- Machine specific parameters pre-configured

- Cabling between major control units provided

MS-Tech offers an optional, quick installation service for its CNC control package, designed to minimize machine downtime. Typically, two MS-Tech technicians can have a machine retrofitted and operational within 4 work days from arrival. For a quotation regarding our installation service, please contact us directly via phone, email, or eBay message.

Core features for retrofitters:

The following features are intended to help retrofitters to expedite and simplify the retrofitting process. MS-Tech’s CNC control package has the following features:

- Built-in PLC and ladder programming utility for I/O control

- Built-in PID tuning utility for servo performance tuning

- Built-in diagnostic utility for system trouble-shooting

- Built-in macro for automatic tool change control

Intuitive User Interface:

MS-Tech CNC is capable of doing complicated machining jobs with ease of operation and programming. Our user interface was designed to provide operators with the greatest convenience for day-to-day use — a typical operator can learn how to use MS-Tech’s CNC system within 20 minutes. A full PDF operator manual will be provided with the CNC package.

A customer wrote to us: “As we bring in additional employees and more people interact with the MS-Tech controls, the feedback is always very positive and everyone remarks how easy and user-friendly the controls are to use”.

Servo Motors and Drives:

Servo drives and motors are not included in MS-Tech’s listed price. MS-Tech’s CNC control system can interface directly with your pre-existing motors and drives for most of the Cincinnati VC model number machines. However, new MS-Tech servo motors and drives can be ordered to prevent issues from outdated and worn drives, as well as save time by directly interfacing with MS-Tech’s CNC solutions. Please contact MS-Tech for pricing and delivery information.

The following parts list covers the basic components included in each MS-Tech CNC control retrofit package. Our engineers customize each package for your specific machine, so final parts list may include additional items.

| Item | Quantity | Description |

|---|---|---|

| 1 | 1 | Operator panel unit (OPU) A closed unit ready for being installed in front of a machine. The OPU consists of a built-in 15" LCD color display, an MDI input device, a manual pulse generator, and pushbuttons of Emergency-Stop, Cycle-Start, Feed-Hold, etc. |

| 2 | 1 | Motion controller unit (MCU) A self-cooling, highly-reliable, industrial-grade motion control computer with a solid-state hard drive, built-in PLC, etc. |

| 3 | 1 | Signal connection unit (SCU) It is a control signal connection unit for connecting to/from OPU, MCU, servo drives, spindle drive, relays, and magnetic contactors. It has built-in optically-isolated home switch inputs, limit switch inputs, general purpose inputs and outputs. |

| 4 | 1 | Power supply unit #1 (PSU1) For supplying power to OPU, MCU, and SCU. |

| 5 | 1 | Power supply unit #2 (PSU2) For I/O switch use. |

| 6 | 1 | Mouse tray To be attached to the bottom of the OPU. |

| 7 | 1 | USB mouse |

| 8 | 1 | I/O expansion board (IOX) For controlling solenoid valves and receiving input signals |

| 9 | 1 | One set of I/O modules for DC inputs, AC outputs, DC outputs. The actual types and quantities are depending on the machine to be retrofitted. MS-Tech willmakesure to ship enough I/O modules. |

| 10 | 1 | Licensed MS-Tech CNC control software Pre-installed in the MCU for your specific type machine. |

| 11 | 1 | One set of customized machine data files. MS-Tech will install the right machine data files for the type of the machine you ordered. |

| 12 | 1 | Operator manual in PDF format |

| 13 | 1 | Integration manual in PDF format |

| 14 | 1 | Reference wiring diagrams in PDF format |

| 15 | 1 | OPU power cable For connection from SCU to OPU |

| 16 | 1 | OPU Pushbutton cable For connection from SCU to OPU |

| 17 | 1 | OPU eHMI cable For connection from MCU to OPU |

| 18 | 1 | OPU USB extension cable For connection from MCU to OPU |

| 19 | 1 | SCU control signal cable For connection from MCU to SCU |

| 20 | 1 | IOX expansion cable For connection from SCU to IOX |

| 21 | 1 | There may be other components that MS-Tech deems necessary based on experience |